|

AGTServices Inc.24 Sam Stratton Rd |

On-Site Generator Services Performed in the Following Locations:

USA, Canada, Mexico, Hawaii, Caribbean, Argentina, Venezuela, Italy, & England. Will entertain other countries upon request.

Generator Test, Inspection & Repair

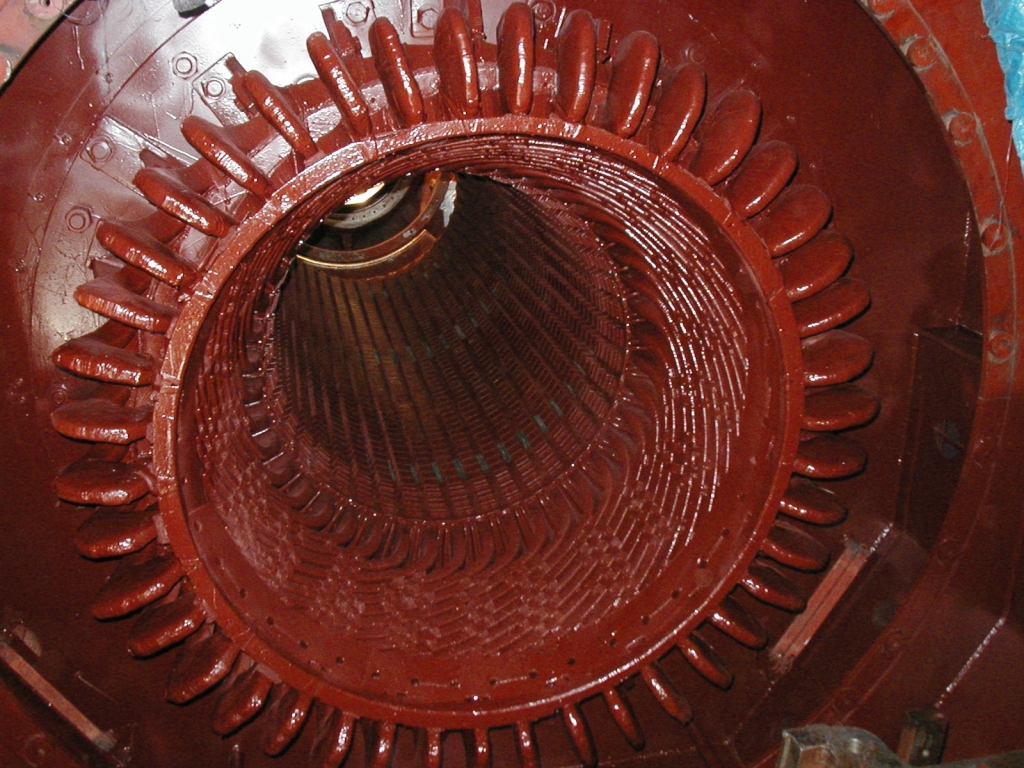

AGTServices specializes in providing time saving (value-added) testing and repair solutions, coupled with expert replacement/upgrading and expedited delivery of custom components to repair any steam or gas turbine generator — fossil and nuclear.

AGTServices can provide on-site or off-site services and provide replacement parts for any make or model of generator in the power generation industry. Our newly expanded 35,000 square foot service facility is equipped with the latest innovations for the testing and repair of generators, readily stocked with the most critical replacement materials, and tooled to undertake any emergency generator stator or field need. Equipped with 75 ton crane capacity and easily accessible to the NY State Thruway, our service shop is capable of servicing almost any size generator.

In the newly expanded facility, AGTServices has the capability to manufacture new high voltage bushings as well as refurbish existing HVB’s to “as new” condition. We stock a variety of porcelains and stand-off insulators to ensure the shortest cycle possible to minimize downtime.

Testing Services

Testing Services

AGTServices maintains its own fleet of calibrated generator testing equipment. In emergency situations, most equipment can be shipped, counter-to-counter, to arrive with the Generator Specialist. Comprehensive generator testing and immediate interpretation and analysis of results is our commitment to you.

- Hi Potential Testing (D-C & A-C)

- Winding Resistance Testing

- Insulation Resistance Testing

- Stator Water Cooling System (Pressure/Vacuum Decay) Testing

- Helium Trace Gas Testing

- Capacitance Mapping

- Stator Wedge Surveys (Manual & Automated)

- EL CID Testing

- Core Loop Testing

- Core Tightness “Break Away” Checks

- Doble Testing

- End Winding Resonant Frequency “Bump” Testing

Repair Services

AGTServices employs some of the most experienced OEM-trained winders in the industry. Our typical winder experience ranges from wedging five MW stators to rewinding 1100 MW water cooled units.

Stator

Stator

- Stator Rewinds

- Stator Rewedges

- End Winding Repairs

- Water-Cooled Leak Repairs / Clip Replacement

- Bar Vibration Abrasion Repairs

- Stator Core Restacking/Repair

- Through Bolt Replacement / Building Bolt Tightening

- High Voltage Bushing Change-Outs

- Stand-Off Insulator Change-Outs

Rotor Services

- Retaining Ring Removal/Replacement

- Winding Elongation/Coil Distortion Repairs

- Partial/Full Rewinds

- Main Lead Replacements

- Rotor Dovetail Cracking Preventative Maintenance

- Collector Ring Replacements & Resurfacing

Expertise & Experience

AGTServices has over 200 years of combined, proven OEM engineering design and hands on experience, and is known in the industry for its schedule conscious, cost-effective solutions with respect to generator testing and repairs.

Other Relevant Background or History

AGTServices and NEC have successfully completed projects ranging in scope from as simple as a top bar replacement to as complicated as a complete stator rewind of a Westinghouse inner gas cooled generator. Over the past ten years as demand grew, AGTServices has always been able to count on NEC to come through to meet our customers needs.